Welcome to

Sunny Glassware, if you are glassware buyer, you can take a second to learn more about the production process of glassware as following.

1.Raw Materials-->2.Dissolution -->3. (Artificial Mechanical forming ) molding -->4. Polishing--> 4. Annealing-->5. Quality inspection and packaging

【Raw materials】

The main raw materials of glass: quartz sand, limestone, feldspar, soda ash, boric acid, etc.

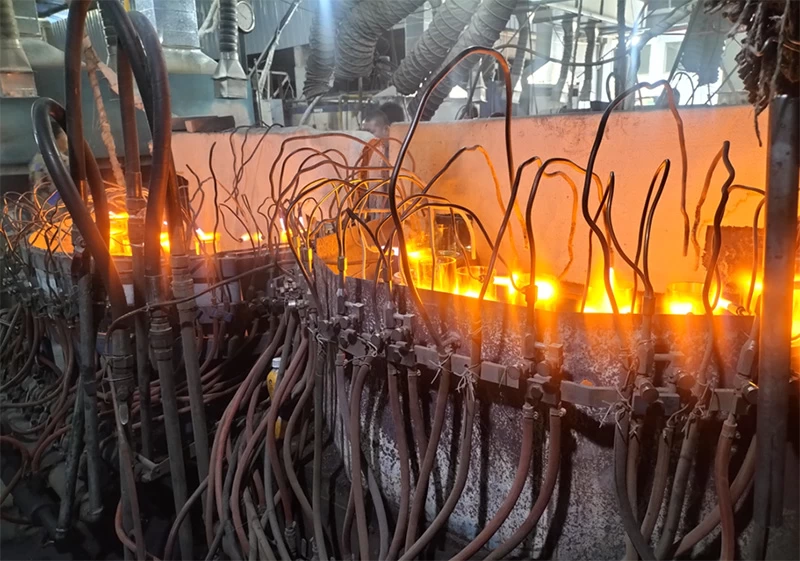

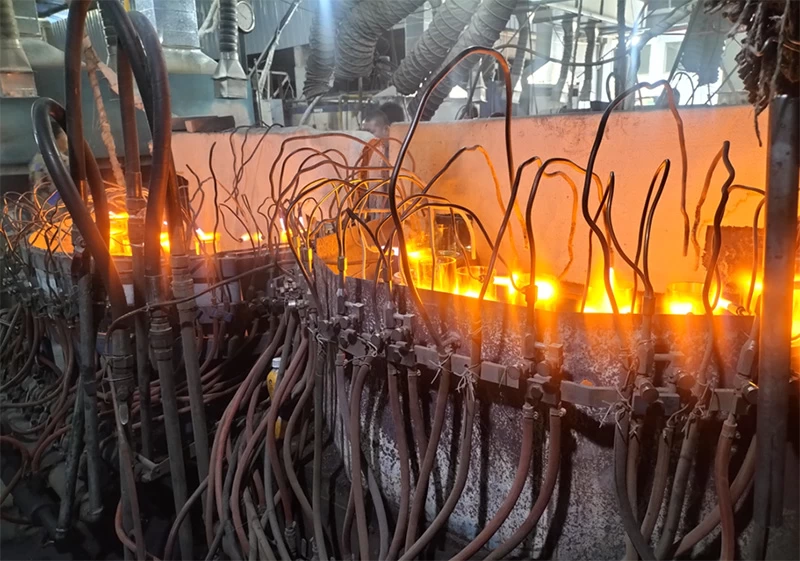

【Dissolution】

The matched raw materials through the furnace high temperature heating, forming no bubble glass liquid; most seen with flame heating, also a small amount of current heating, called electric kiln.

【Forming】

Convert the molten liquid glass into a solid product with a fixed shape. The forming method can be divided into two categories: artificial molding and mechanical molding

1) Artificial molding

A, artificial blowing with a nickel-chromium alloy blowing pipe, pick a ball of glass in the mold while turning while blowing, mainly used to form glass bottles and glass balls; In b, diversified shape and thin cup wall; In c, the cup body has slight bubbles, pattern, inclined bottom and size specifications, weight differences.

After blowing into a small bubble, another worker with the top plate to stick, two people while blowing while the pull is mainly used to make glass tubes or rods.

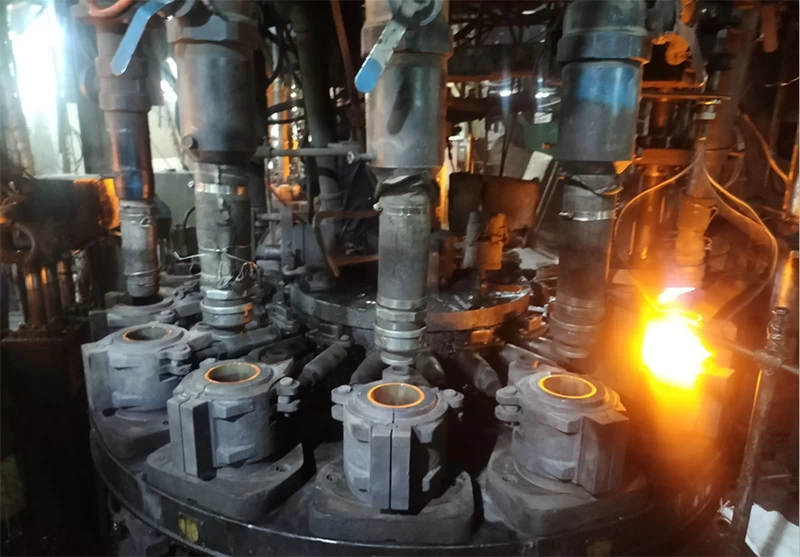

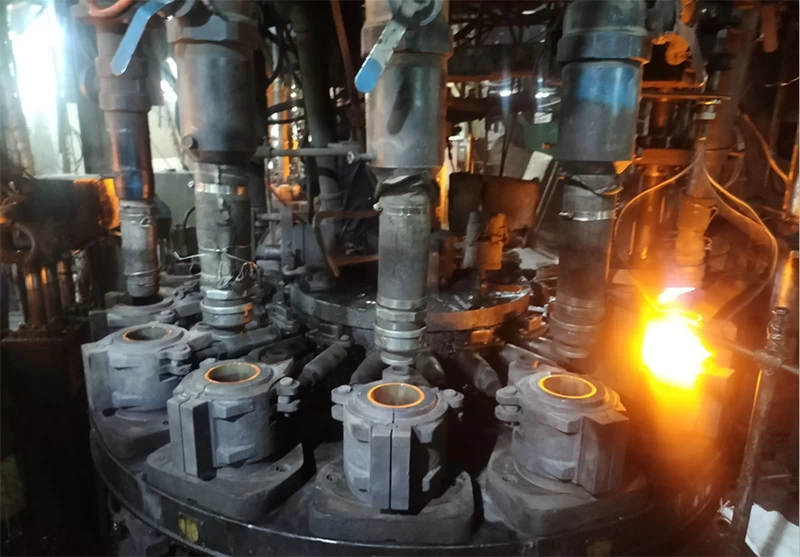

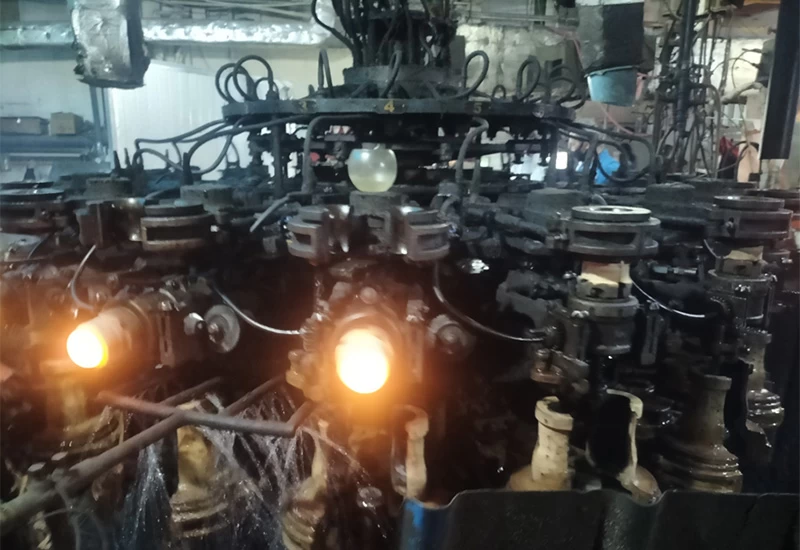

2. Mechanical forming

a. The press molding flows out from the outlet of the glass melting furnace, and the gob of the set weight is formed by the feeder, which is cut into the mold and punched by the punch matching the mold;

b. The mold exchange of each station is synchronized with the up and down stroke of the punch. The glass liquid enters the pressing mold through the feeding pipe, and then the punch is pressed down rapidly to form. The upper part of the punch is equipped with a cover to make the glass Liquid forming, and the function of the cover plate makes the mouth of the forming glass blank relatively flat;

c. The mold plays a key role in the molding process, relying on the surface of the mold for direct molding. For example, if the mold temperature is too high during the molding process, the mold will stick to the mold, resulting in product deformation. If the mold temperature is too low, it will cause the product to have cold streaks. , relying on the past experience of the master and product parameters to adjust and correct;

d. The cooling during the molding process of the product should be reasonable. If the cooling system speed is too fast or the cooling design is unreasonable, the temperature of the product will be uneven, especially for thicker products, there will be large temperature differences, resulting in excessive internal thermal stress. Explosion phenomenon during the molding process;

e. There are four kinds of common molds: top mold, automatic edge mold, manual mold opening, and explosion mold. If the cup opening is small, the top mold is suitable for the top mold without a clamping line, and the cup opening and the cup bottom are the same size, which is suitable for automatic opening mold. , The cup body has 2 clamping lines. Some cups with patterns or logos need to be opened in three or four or four times. It is suitable for manual mold opening or explosion mold. The cost of manual mold opening is lower than that of explosion mold. The operation is to close the mold and open the mold, while the explosion mold is mechanized, the pattern of the cup body is more complicated, and the deeper the mold can only be opened manually;

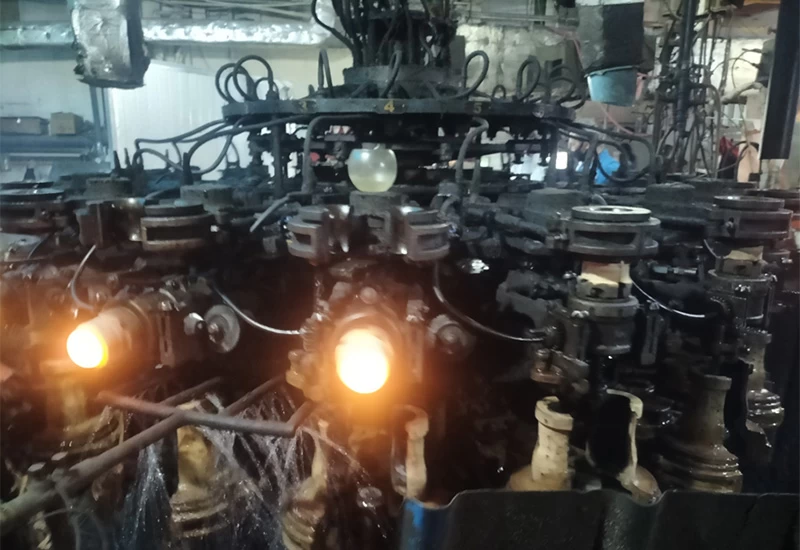

Machine blowing molding from the glass melting kiln outlet outflow, through the feeder to form a set weight of the material droplets, cut into the primary mold blowing and then into the molding mold blowing into products, after forming for hot cutting; Machine blowing cup wall is thick, the size and specifications, the weight is basically the same, the buoyancy is not so large, the product output is relatively large, the style is relatively simple.

【Polishing】

1.There are two kinds of single throw and double throw, the product comes out from the mold, the surface has no finish, need to be polished to make the product to achieve the desired finish;

2.Adjust the position and size of the musket and trachea, musket and trachea are complementary to each other;

3.The effect of single throw finish is not as good as the effect of double throw finish, because double throw can be thrown in many aspects

【Annealing】

The glass has undergone severe temperature changes and shape changes during the forming process, which will reduce the strength and thermal stability of the glass. If it is directly cooled, it is likely that the glass will self-cold burst during the cooling process or after storage. Explosion phenomenon, glass products must be annealed after forming; the temperature rises from low to high, from more than 400 degrees to three stages or four stages to adjust more than 500 degrees, annealing generally takes 3-4 hours to complete; check the annealing effect Need to test, such as hot and cold test, scratch test, etc.

【Quality inspection and packaging】

1. When the products at the end of the kiln come out, first compare the samples and measure whether the size, weight, and capacity meet the requirements;

2. Take a row of products online for cooling and stress testing, such as scribing and hot-cold testing to determine product stress Whether it meets the standard, if the stress does not meet the standard, then the speed of the line can be slowed down and the temperature can be raised; 3. The defective products that appear in the production process, such as material grain, material slag, cold grain, cold frying, etc. Inspect "At the same time inform the machine master about the defect of the product, and ask for a timely solution", and then pack it into the box.