Sunny Glasswarewas established in 1992, The quality control of the

products is the primary focus. Each inspector of the QC team must undergo pre-job training and can only be employed after passing the assessment. The average work experience of the inspectors in Sunny Glassware for more than 5 years, there have been no major quality complaints for more than 10 consecutive years. Let's take a look at the daily work of our inspectors

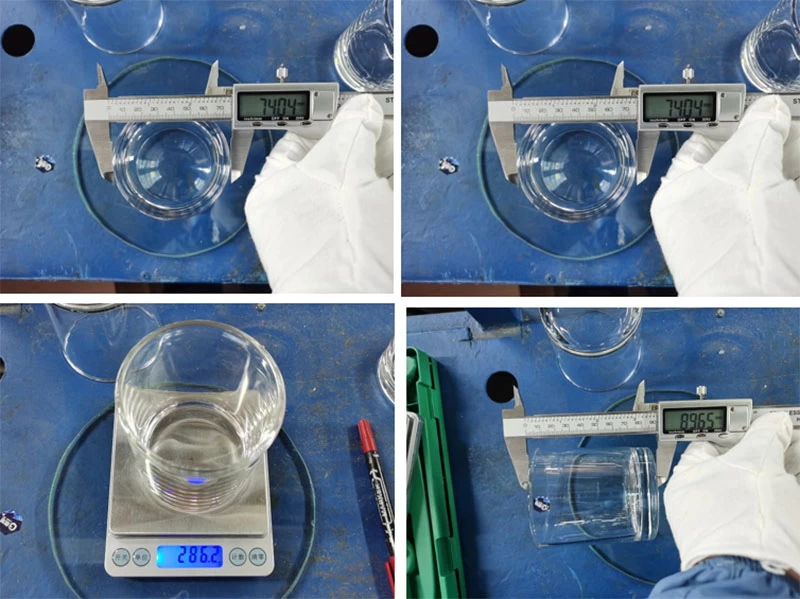

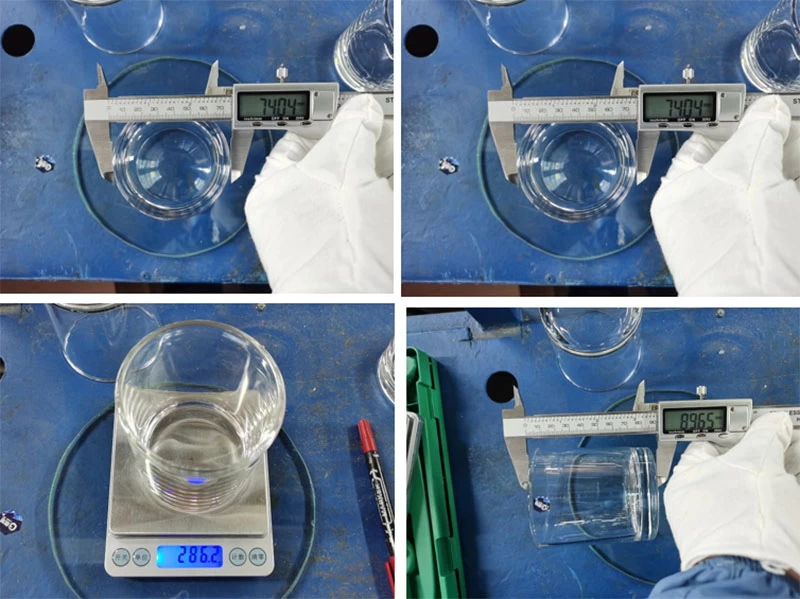

Essential tools for inspectors:Electronic scales, stalk ruler, leather ruler, rolling ruler, steel ruler, thermometer, glass knife, oily mark.

One of the routine work:Clear glass cup inspection

The clear glass cup inspection process can be divided into Pre-judgment inspection, patrol inspection and sampling inspection

1 Pre-judgment inspection:

The pre-judgment inspection refers to the prediction and understanding of the product before entering the kiln. This process is mainly to understand the weight, appearance, molding and even size of the product, to see whether it meets customer requirements. Secondly, when there is a problem, the factory in the adjustment process, we can also understand whether to improve and the degree of improvement, so as to find the problem and strive to control the problem in the bud state.

2 Patrol inspections

Inspection 1:

This process is not stable because the product has just come out of the kiln, so it may last for four to five hours, or even longer. At this time, we can check a preliminary understanding of the product and the sample signing, forming, weighing the weight, the size and even the appearance, and check the data and customer requirements. Find abnormal timely communication to deal with, control the problem before the packaging.

Inspection 2:

This time period is close to stability. Therefore, to check the details of the products out of the kiln, whether the appearance and other changes, and must be uninterrupted general interval time of 1 hour once, and the time is not less than 20 minutes of online inspection. Find problems and timely feedback to the responsible person. If necessary, properly remind the workers of the production line and customer requirements, and control the flow of defective products into the packaging.

Inspection 3:

When online products tend to stabilize, do not take chances. Because, there are too many uncertainties in each time period. In addition to the visual inspection by experience, during this period, when necessary, tools can be used to the bottom of the product and mouth flatness inspection, such as glass, ceramic tile and other plane detection bottom or mouth shaking bottom or shaking mouth phenomenon. Secondly, you can use the caliper to detect the bottom of the cup and the edge mouth phenomenon.

Inspection 4:

The size of the production line, the inspection must be carried out in accordance with the data and sample signing requirements, usually the reference sample signing (because the sample is usually confirmed by the guests) should be handled and solved in time. When the product size or gram weight does not meet the requirements, the factory is bound to bring negative problems in the adjustment process. At this time, we should judge the primary and secondary problems, timely feedback and communication, and grasp the key points when not violating the customer requirements.(If the guests pay attention to the capacity, we can appropriately increase the weight to solve other negative problems of the product.) Of course, this situation is generally a new product or a difficult problem to solve at the moment.

Inspection 5:

For product wall thickness, bottom thickness detection and capacity testing to ensure that the product meets customer requirements. Secondly, the uninterrupted spot checks of the production line packaging are mainly to timely discover problems in time to remind the production line workers' inspection products and packaging processes to pay attention to bad products mixed in packaging. If the production line is found to be poor, the ratio is large, and the factory must be inform the factory in time and then eliminate bad packaging.

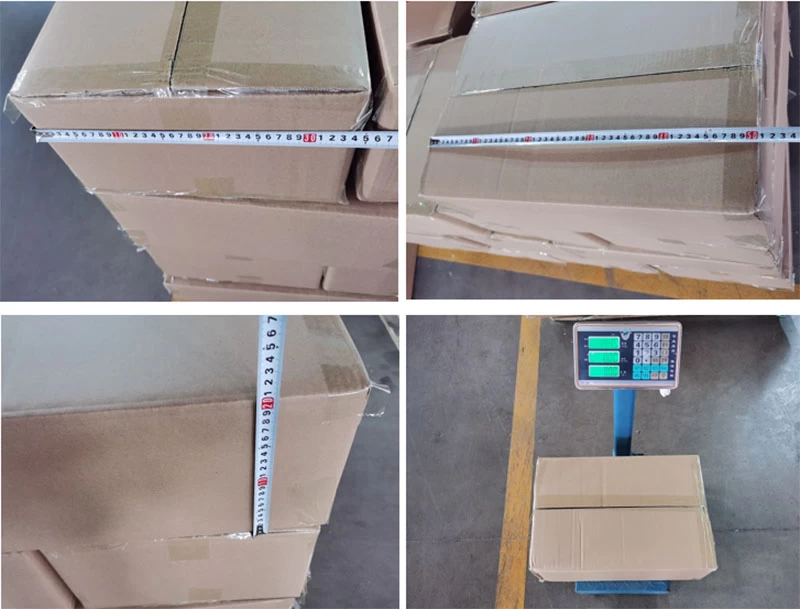

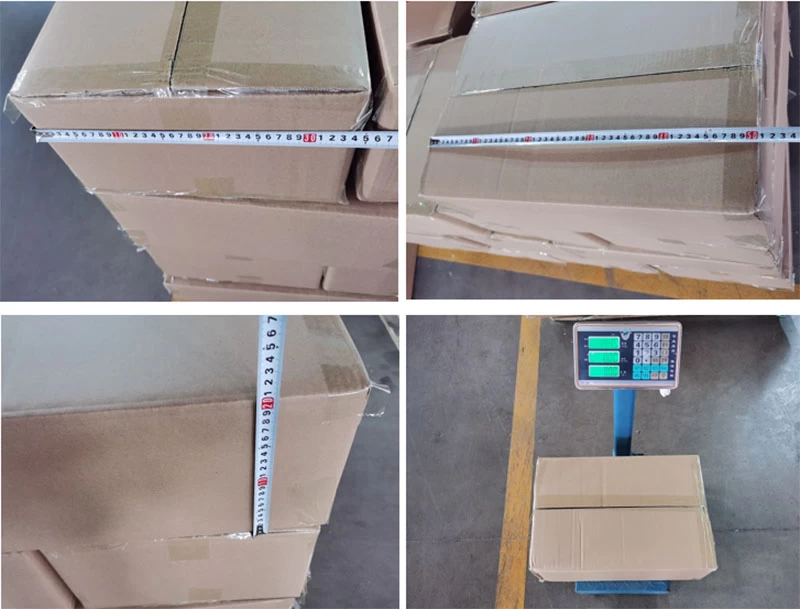

Inspection 6:

Mainly check whether the outer box material, size, weight, and packaging will affect the product during packaging. This process check is mainly to pay attention to whether the packaging workers and the outer box meet the product packaging requirements. (Especially the entrusted product) At this time, it is easy to cause the second damage, damage and flowering phenomenon of the product, so the inspection of this process needs to pay special attention and remind the factory and the production line packaging. Dismiss

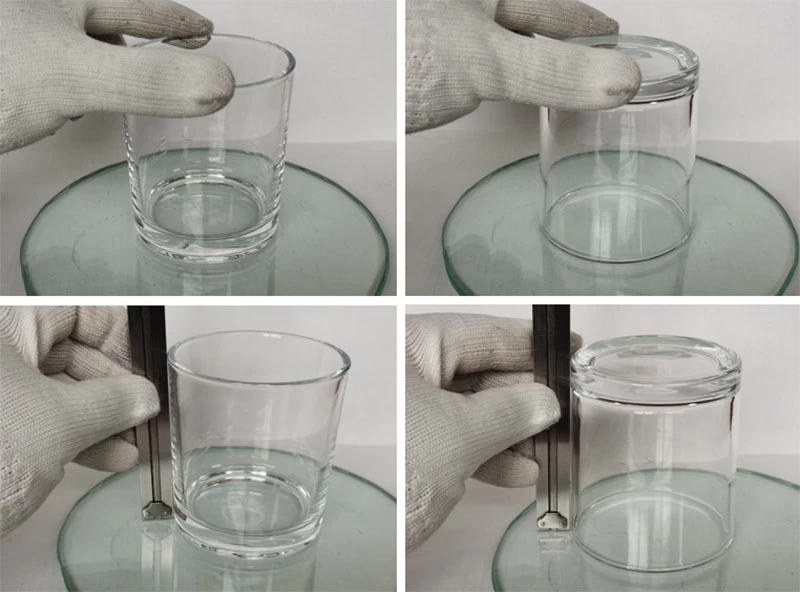

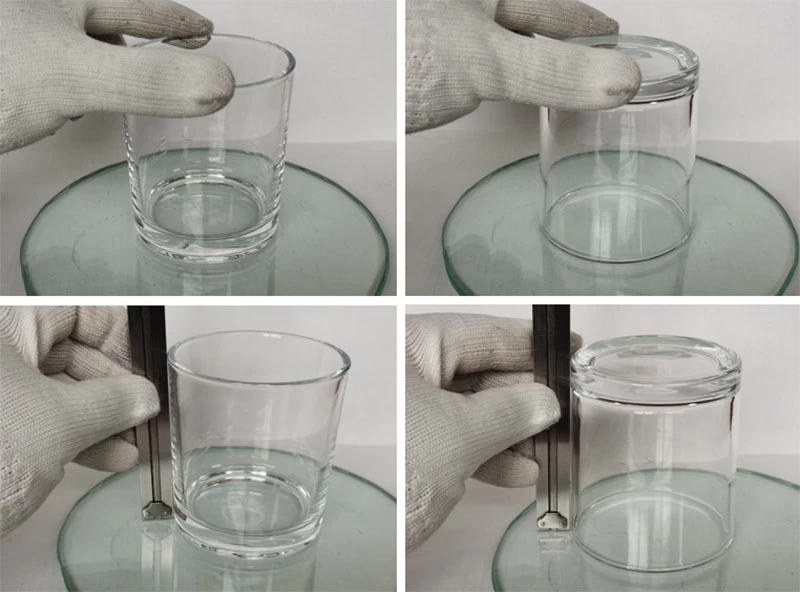

Inspection 7:

The cap functional inspection, the supporting cover provided by the general customers is fixed for molding, so it is necessary to adapt to the product on the production line without interruption. Phenomenon

Inspection 8:

Inspection with a silicon glue cover, when producing this can and cover of the production line, a few more silicone ring rotation is required for use. This process needs to ensure that the lid and the cup match the force OK. Not too tight. Therefore, the production line must be uninterrupted test effect

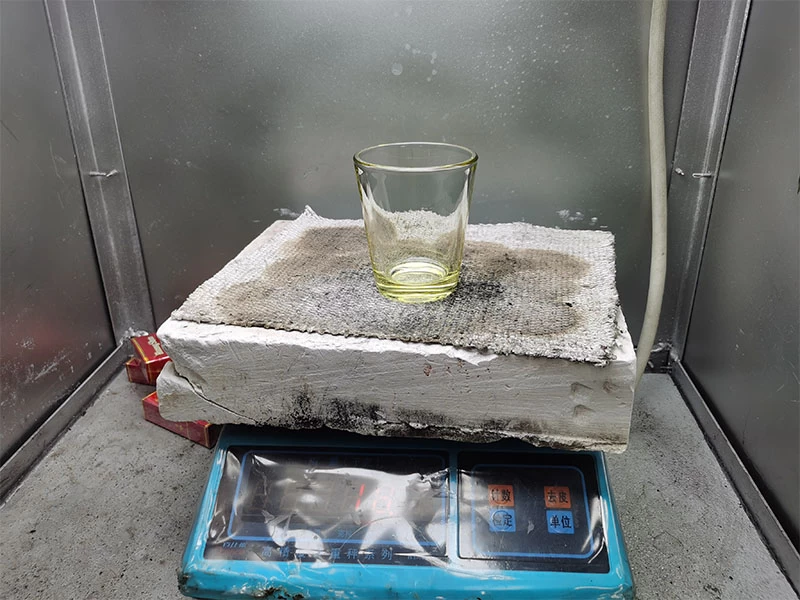

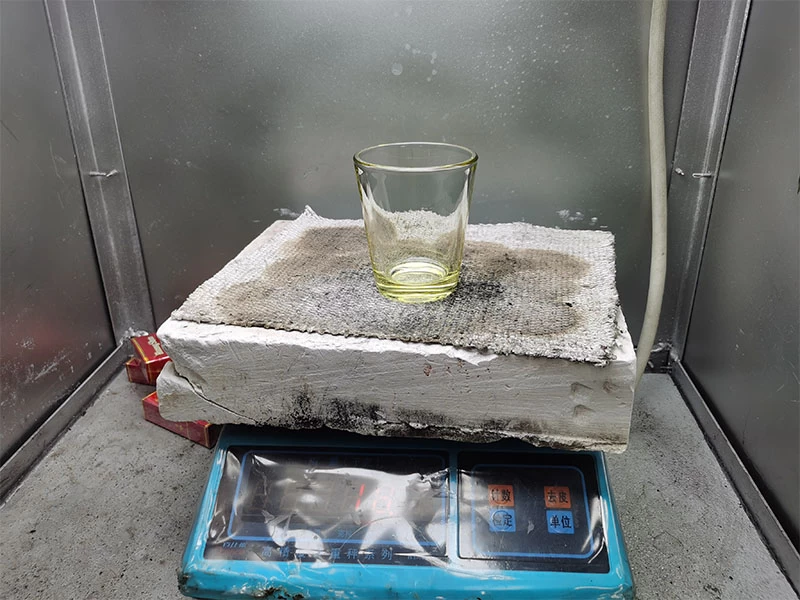

Inspection 9:

Product stress test, generally 2 hours after the product is out of the kiln, do a stress test after 2 hours. We better choose the test time after 3-4 hours or the next night shift product test.

3 Spring check:

Usually, the products and tail goods produced by the factory in the night shift are generally carried out the next day. The night shift products are relatively scattered. The problems of each time period are different. This is mainly related to the fatigue operation of the night shift workers. Therefore, I usually have more products at 2-5 am at night shifts at night shifts. Taking this point as the key inspection, many times this matter is the most prone to problems. Secondly, the inspection of the night shift is performed. Generally, the factory hopes to return to work for the problem of each entrustment.

Inspection reports

The inspection report is the assessment and interpretation of the product quality of the product. Generally, we are presented to the customer in the form of text descriptions and pictures. This allows customers to intuitively understand the content of the report and the overall quality of the product. And timely grasp the quality conditions, quality changes and existing problems in the production process. In order to make correct judgments and take effective decision -making measures.